SEFAB’s Range of Gutters for Various Applications

Trimline Gutters

Trimline gutters, designed for high-capacity water flow, are ideal for industrial and agricultural buildings with profiled steel roofing and cladding. The gutters are individually designed to suit roof pitch and roof sheet profile.

This range of gutters are typically manufactured in the same material as the roof and cladding sheets (plastisol or painted finishes) and can either match the colour or be a contrast for architectural aesthetics. The inside leg of the gutter is fixed to the underside of the box profile sheet and a gutter support arm is used to extend the crown of the sheet and support the outside of the trimline gutter.

The gutters are typically supplied in 3m lengths which are joined using internal butt straps and fixed in place using stitcher screws (or rivets) and sealant. Gutter outlets and stop ends are generally supplied loose.

Where a gutter runs around the perimeter of a building the gutter profile can be fabricated into external or internal corners eliminating the need for mitring and fixing on site, reducing labour time and the likelihood of leaks.

Hoppers, square downpipes, downpipe shoes and adaptors can be manufactured in the same material and colour as the gutters.

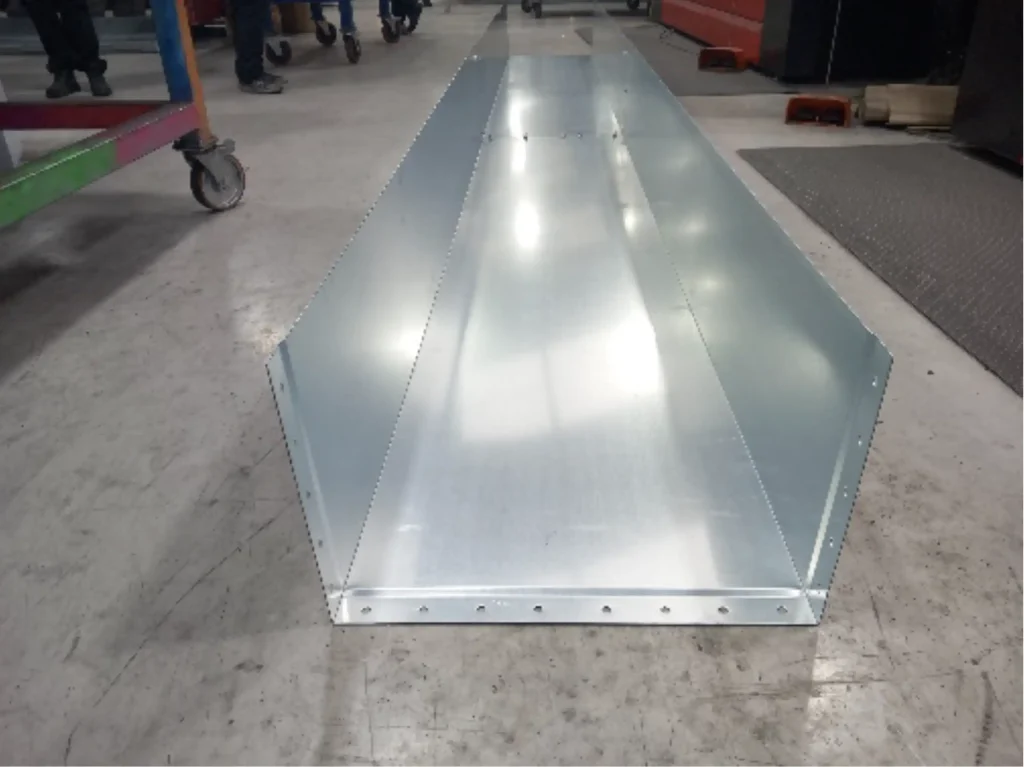

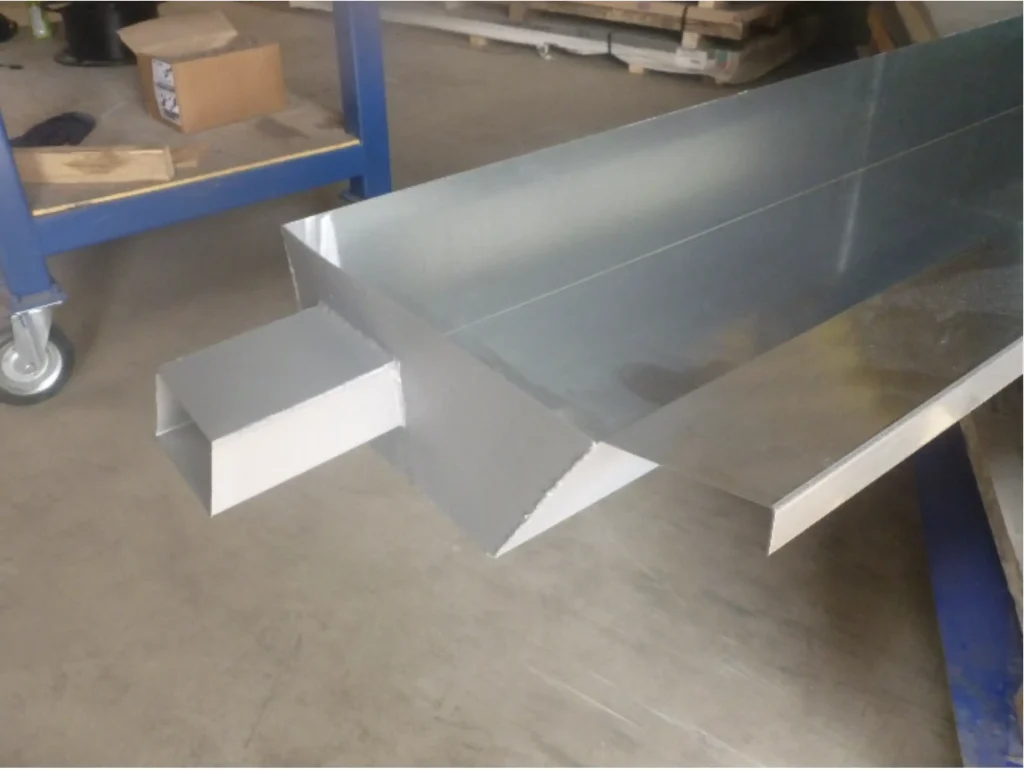

Heavy-Duty Box Gutters

Heavy-duty box gutters, available in heavier gauge (1.5mm, 2.0mm or 3.0mm thick) galvanised steel or aluminium, are a versatile solution and used predominantly on industrial and agricultural buildings although they can be utilised on domestic properties. This range of gutters, typically produced in 3m lengths but also available in 4m, are manufactured to your specification and can be joined in two ways:

- Internal butt strap system using bolts, nuts and mastic which require drilling on site as required

- Joggle jointed system where a joggle is formed in one end of the gutter and the next length of gutter is laid inside and fixed in place through pre-punched holes using bolts, nuts and mastic. Captive nuts can be supplied where there is no underside access.

Stop ends can be supplied as loose or welded in place. Weir overflows can be incorporated into the stop ends if required.

To prolong the life of galvanised gutters it is recommended that the inside of the gutter is painted with a bitumen or waterproofing sealant.

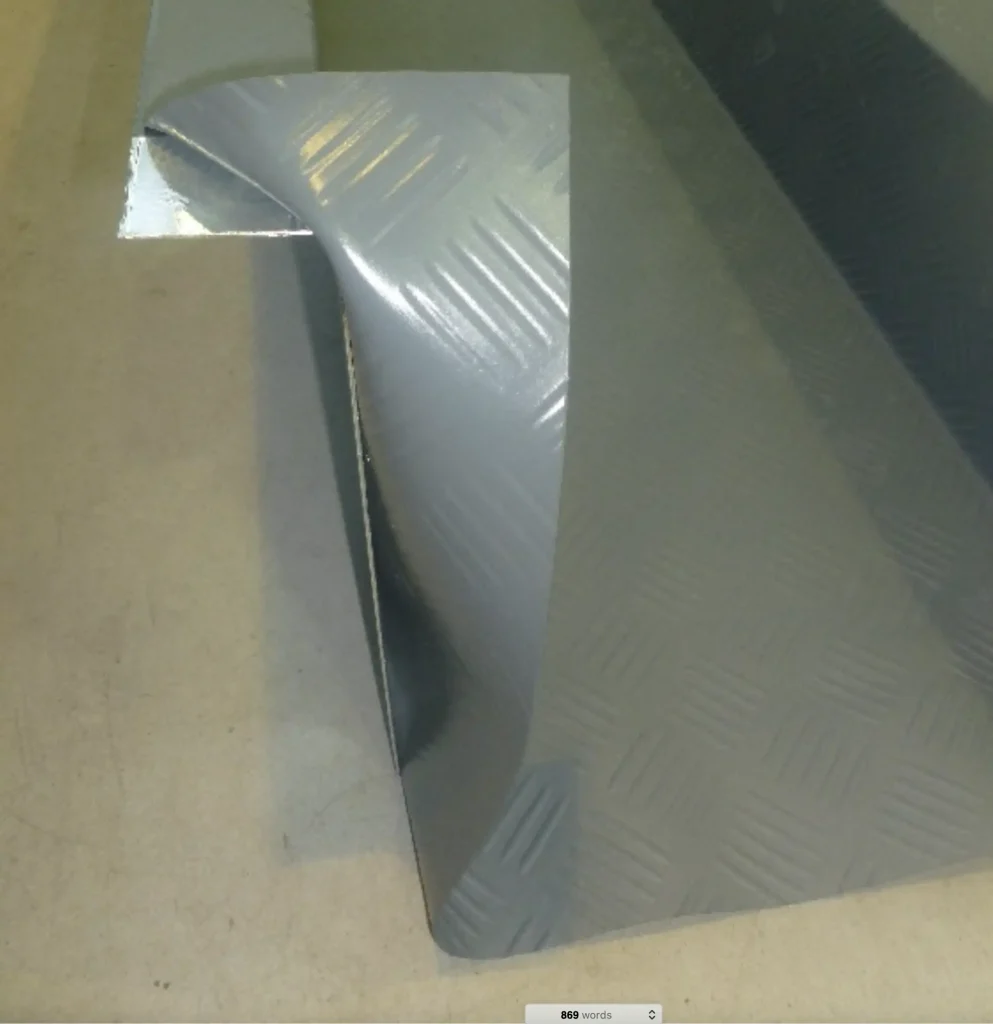

Membrane Lined Gutters

Our membrane lined range of gutters feature a 1.2mm PVC membrane factory bonded to a 1.2mm galvanised substrate.

This configuration ensures a watertight seal, making them ideal for applications requiring superior water resistance. A 75mm long flap is provided at the ends of the sheets for joining onto the next gutter. This end flap is heat welded at the joints on-site to form a watertight join.

Custom Gutters

All our gutters are made to your specific requirements. Our team will work with you and provide technical advice, if required, discussing options for different gutter types/materials to ensure you are provided with the best gutter type for your project.

Technical Considerations for Gutter Selection

When selecting gutters it is essential to consider the following:

- building type,

- roof design (size angle of slope),

- required lifespan

- number and size of oulets/downpipes

- access for installation.

Installation and Maintenance

Proper installation is critical for ensuring the longevity and performance of the gutters. We can supply all necessary fixings and sealants for joining the gutters.

Implementing a regular maintenance program, including clearing debris and checking for corrosion and leaks, is essential to prolong the life of the gutter.

FAQs About SEFAB’s Range of Gutter Solutions

1. What types of gutters does SEFAB manufacture? SEFAB manufactures a range of gutters including trimline, heavy-duty box, and membrane-lined, suitable for various building applications.

2. What materials are used in Trimline gutters? Trimline gutters are typically manufactured from 0.7mm thick plastisol, prisma, polyester coated and even galvanised or aluminium (mill finish or powder coated) sheets.

3. For what applications are heavy-duty box gutters suitable? Heavy-duty box gutters are primarily used in industrial and agricultural buildings but can also serve as valley gutters for domestic properties.

4. How are heavy-duty box gutters joined? They can be joined either using an internal butt strap (requires drilling on site) or a pre-punched joggle jointed system. Nuts, bolts, washers and sealants are also supplied.

5. What are membrane lined gutters? These gutters feature a 1.2mm thick PVC membrane bonded to a 1.2mm thick galvanised substrate, providing superior water tightness. A 75mm long end lap is provided for heat welding the joins.

6. Can SEFAB manufacture custom gutters? Yes, all gutters that SEFAB manufacture are made to your specific requirements.

7. What lengths are the gutters available in? Most gutters are manufactured in a standard 3m length, but some finishes and colours can be offered in 4m lengths.

8. Are stop ends and gutter outlets provided? Yes, stop ends and gutter outlets are available and can be supplied either loose or welded/fixed in place.

9. Can SEFAB supply the ancillary rainwater goods? Yes. Downpipes, swan necks, downpipe shoes, hoppers and brackets can all be manufactured in the same material as the gutters.

10. What maintenance is required for SEFAB’s gutters? Implementation of a regular maintenance program is recommended to prolong the life of the gutter. This should include clearing debris and checking for corrosion and leaks.

Join the conversation